In this technologically advanced time, fast, precise, and cost- and time-efficient laser cuttings are highly appreciated. If you are also into the metallic service industries, you must be familiar with the CNC beam emission technology. Which is far better than the traditional metal-cutting machines. However, we must adhere to certain criteria, like metallographic materials, depth of cuttings, and other related parameters. So, here, mostly, we shall be discussing the industries that take parts into the laser cutting services.

What are the CNC laser machines for the metallic cutting precisions?

For any laser cutting service needs, computer numerical control (CNC) machines are requi. And these machines consist of auto-generated programming that automatically fixes the desired cutting programs and commands. So, here we need fiber laser cutting machines, CO2 laser cutting machines. It comes with different power categories like 1 kw, 2 kw, and onwards. However, for the high precision of the different metallic materials, CNC machines are quite efficient.

Top Industries that takes part

Laser cutting is a versatile and precise technology widely used in various industries for cutting and shaping metal materials. Some major industries that heavily rely on laser cutting for metal processing include:

- Automotive Industry: Laser cutting fabricates various automotive components, such as chassis parts, body panels and many others.

- Aerospace Industry: In the aerospace sector, laser cutting machines creates precise and lightweight components. And for aircraft and spacecraft, including structural elements and engine parts.

- Sheet Metal Fabrication: Companies involved in sheet metal fabrication use laser cutting for creating precise cuts in sheet metal. So, to produce components used in construction, HVAC systems, and other applications.

- Electronics Manufacturing: In electronics industry for precision cutting of metal components, we also use CNC machines.

- Medical Device Manufacturing: The medical industry utilizes laser cutting for manufacturing surgical instruments, implants. And various medical device components due to its high precision and cleanliness.

- Jewelry Manufacturing: Laser cutting in the jewelry industry enhances its market value for creating intricate designs and patterns on metal pieces.

- Architectural and Construction Industry: Metal components fabrication in architectural structures, building facades, and other construction based works.

- Defense and Military Applications: Laser cutting is utilized for manufacturing precise components for military equipment, vehicles, and weaponry.

- Consumer Goods Manufacturing: Various consumer goods, including appliances and furniture, incorporate metal components produced using laser cutting technology.

- Custom Metal Fabrication: Many companies specializing in custom metal fabrication services use laser cutting to fulfill specific design requirements for their clients.

- Tool and Die Making: Laser cutting is used in tool and die making to produce accurate and intricate shapes for molds and dies used in manufacturing processes.

The advantages of laser cutting, such as high precision, speed, and the ability to cut complex shapes, make it a preferred choice for many industries where accuracy and efficiency are crucial.

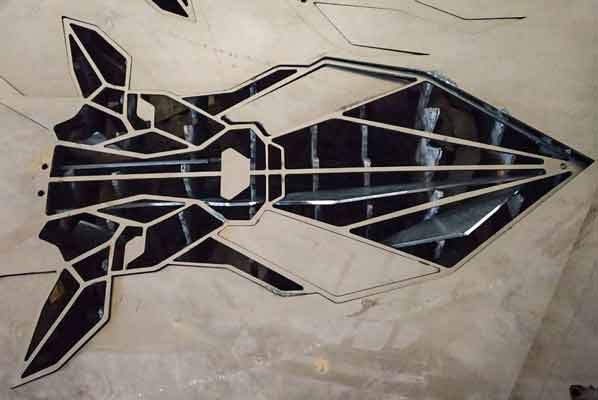

Samples for metallic cutting

Final Words

Finally, we conclude here that for the metallic cutting precision work, we need to get into the CNC laser beam emmission technology. And with these services, you can easily identify your needs as per your related industries. In addition, modern beam erosion technology has drastically reduced time and effort compared to traditional machines and created damage-free final products.