Being a transformational era in laser cutting technologies, the laser service industry has emerged to provide fast, reliable, and damage-free laser services. Here your business requirements will be fulfilled with our latest laser beam technologies. To enhance the productivity of the business in metal fabrication, blending, cutting, and much more. We need to analyze the CNC software programming to set the required design for the final command.

What Can Be Expected Here?

Although, we manufacture the top versions of CNC machines, However, we recommend bringing your required configuration and design samples to process the further software-based commands. Also, here is some of the service info, that our future and current clients can expect from us:

- Higher accuracy level: Irrespective of the material surfaces, the higher accuracy level is maintained using the laser machine. In addition, we know that the different metallic materials need different accuracy levels to maintain the complex shapes and intricate designings.

- Innovative Ideas: If you are not sure about your business needs and requirements, our machines’ CNC-based software programming helps in creating the cutting depth and the material category to proceed further for the proper relevancy. In addition, you can create the design here and give further commands.

- Damage-free work: As the machine is fully automatic, it is capable of creating designs, blending, and cutting works over all the material categories. So, we maintain our services with the utmost and highest- precision to get minimal damage over the metallic materials.

- Low distortion rates: We assure you all the laser services works are done with very minimal heat-affected areas over the metallic material irrespective of the nature of the metallic materials.

- Economical laser services: We maintain all our laser machine-based services at very affordable rates. So, you can easily take the live demos and rely on the services provided by our technicians.

Metal cutting accuracy level

Any high-powered laser cut the metallic material ranging from 0.12 inches to 0.4 inches in thickness. Here are some of the basic metal cutting accuracy levels enlisted below:

- Stainless steel- 3mm-10mm

- Aluminum Plate- 2mm- 8mm

- Copper plate- 2mm- 8mm

- MS- 2mm -12mm

- Brass- 2mm

Furthermore, the cutting thickness also depends on the other factors like

- Material strength

- Laser cutting speed

- cutting Cost

- Laser power input

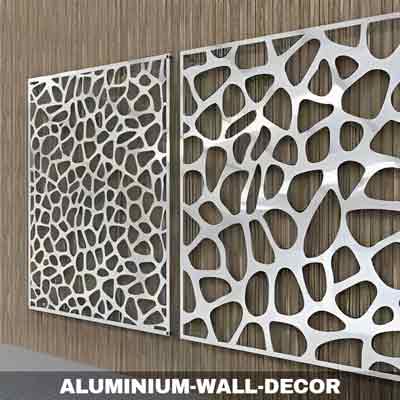

CNC Laser Cutting Samples

Conclusion

A CNC laser is compatible with different metallic materials and can work very efficiently for many years, providing damage-free and high-precision work. So, you can expect our laser services to perform at their utmost level of accuracy. Also, the main services are here are blending, cutting, engraving, designing, and similar others in different sectors like automobiles, manufacturing, and many others.

Frequently Asked Questions

Q1. What is the customer satisfaction level with the services we offer?

Although a CNC laser machine is capable of many cutting, blending, engraving, and designing tasks, you can expect great laser services from our laser servicing team, as they will take care of all your business requirements and suggest the best one.

Q2. What are the safety concerns during the laser cutting operations?

All kinds of laser cutting operations should be done using goggles for eye protection and in a spacious and ventilated room where there is ample scope for fume extraction. In addition, fire extinguishers should be kept to avoid any fire-related issues in the future.

Q3. What are the factors responsible for the precise laser cutting?

Although our CNC laser machines are quite efficient and compatible with all categories of metallic materials. However, we need to do settings of measures, like material depth, type of design, and other related factors, for more accuracy.