Laser beam technologies are the latest way of creating intricate designs and cutting precision with damage-free and sharp edges. All the laser beam emission is automatically adjusted via 0.001 inches (0.025 mm). A laser cutting process is a fast and streamlined process and runs through the inbuilt CNC software programming.

Advantages of laser cutting services

Here are some of the great advantages of taking the laser machine services for your industry:

- Does not require Tool adjustments: The CNC machines are fully automatic. So, it has a self-adjustable tool setup. Here, it works as per the design, 2D complexities, and much more. So, we need not set the tools every time, that a traditional machine requires.

- Less pollution: The machine exhibits minimal pollution, as compared to the traditional machines.

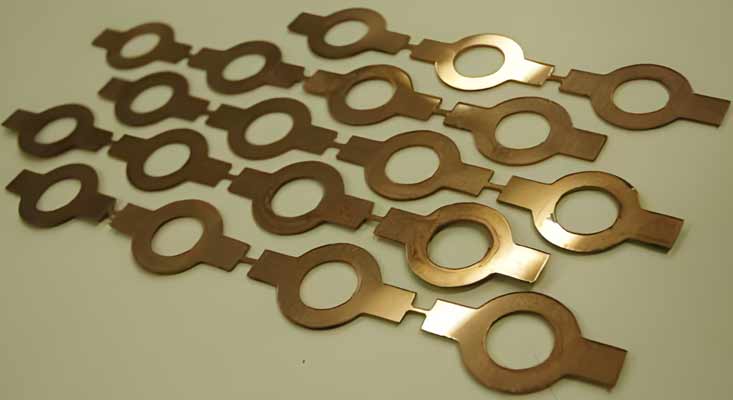

- Material flexibility: A laser machine has variety of metallic and non-metallic materials flexibility, like aluminum, stainless steel, mild steel and similar others. In addition, it has material flexibility with the required cutting and designing depth.

- Precision work: Industries can higher precision work within short span of time.

- Geometrical alteration is easy: You can use the different designs and make the necessary geometrical changes as per your business needs.

- Requires less maintanance: the machine is durable and long lasting with minimal maintaince.

However, it has many other advantages of higher precision, higher speed, and quality work for the related industry.

Diadvantages of laser cutting services

Although it has many advantages, we also can’t deny its disadvantages. So, here are some of the disadvantages of taking the benefits of laser-cutting machines

- Higher initial investment: It will be a bit of an initial investment and upfront costs.

- Emission of Harmful Fumes: You may have chronic health issues due to repeated fumes emission.

- Need skilled operators: The laser cutting operation is a risky job, so it needs skilled operators to handle the work.

Finally, we make a final, damage-free product that is used for multi-industrial needs. And here, we have briefly discussed the advantages and disadvantages of laser cutting machines.